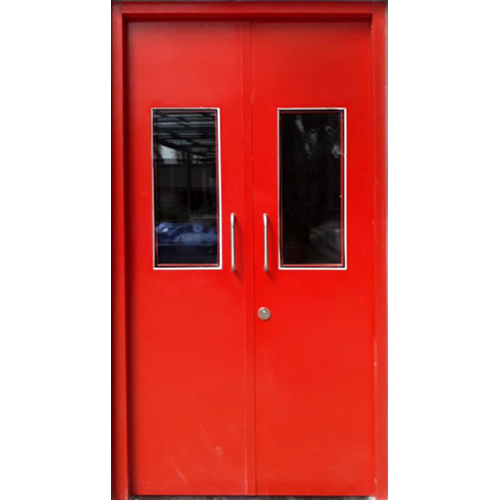

SINGLE DOOR WITH CLEAN ROOM ACCESSORIES

Price 17500.0 INR/ Piece

SINGLE DOOR WITH CLEAN ROOM ACCESSORIES Specification

- Application

- rotect against fire and smoke, maintaining structural integrity under extreme temperatures and delaying fire spread for a specified time

- Feature

- ACCESORIES

- Voltage

- 200 Teraampere (TA)

- Weight

- 60 Kilograms (kg)

- Frame Material

- Other

- Thickness

- 50 AND 80 , 100 Millimeter (mm)

- Air Flow

- 12 Meter/second (m/s)

- Type

- Clean Room Booth

- Material

- Cold Rolled Steel

- Power Consumption

- 100 Kilowatt (kW)

- Dimension (L*W*H)

- 1000X2100 Millimeter (mm)

SINGLE DOOR WITH CLEAN ROOM ACCESSORIES Trade Information

- Minimum Order Quantity

- 5 Pieces

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 10 Days

About SINGLE DOOR WITH CLEAN ROOM ACCESSORIES

A pharma door is a specially designed door used in pharmaceutical manufacturing facilities, clean rooms, and laboratories to maintain strict hygiene, contamination control, and compliance with GMP (Good Manufacturing Practices) and ISO standards. Unlike normal doors, pharma doors are built with smooth, flush surfaces, controlled sealing systems, and materials that prevent particle shedding, microbial growth, and corrosion.

Key Features of Pharma Doors

-

Smooth & Flush Surfaces

-

No sharp edges, joints, or gaps.

-

Prevents dust accumulation and makes cleaning easy.

-

-

Material of Construction

-

Stainless Steel (SS 304/316) or powder-coated galvanized steel.

-

Sometimes high-pressure laminate (HPL) or PVC for non-sterile areas.

-

Resistant to disinfectants and corrosion.

-

-

Air-Tight Sealing

-

Equipped with gaskets / EPDM rubber seals around the frame.

-

Prevents air leakage, ensuring pressure differentials are maintained between clean room zones.

-

-

Flush-Mounted Vision Panels (Windows)

-

Toughened, double-glazed glass windows integrated into the door.

-

Designed flush with surface to avoid particle accumulation.

-

-

Compatibility with Clean Room Protocols

-

Door design prevents microbial growth and particle shedding.

-

Easy to clean with disinfectants and sterilizing agents.

-

-

Automatic & Interlocking Systems

-

Often used with electromagnetic interlocking between two doors (airlocks).

-

Prevents both doors from being open at the same time, avoiding cross-contamination.

-

-

Durability & Safety

-

Fire-resistant designs available.

-

Stainless steel handles, hinges, and closers for long life.

-

-

Types of Operation

-

Manual swing doors for simple areas.

-

Automatic sliding doors for high-traffic sterile areas.

-

Hermetically sealed sliding doors in critical aseptic zones.

-

Durable Material Integration

Constructed with galvanized steel and stainless steel, these fire doors are built to withstand extreme scenarios while ensuring integrity and longevity.

Optimal Size and Weight for Versatile Applications

The fire doors are designed with dimensions of 1000x2100 mm and weigh a manageable 60 kg, making them ideal for both commercial and industrial setups.

Reliable Operational Features

With power consumption of 100 kW and air flow of 12 m/s, the doors are optimized for robust performance and effective functionality.

FAQs of Fire Doors:

Q: What materials are used for the construction of these fire doors?

A: The fire doors are constructed using galvanized steel for the door and stainless steel for the frame to ensure durability and quality.Q: How is the air flow regulated through the fire doors?

A: The fire doors feature capabilities to regulate air flow effectively at 12 meters per second, suitable for controlled environments.Q: Where can these fire doors be installed?

A: These doors are suitable for installation in commercial and industrial setups requiring high durability and safety standards.Q: When and how should these fire doors be maintained?

A: Regular maintenance schedules as per the manufacturers guidelines, focusing on components and airflow mechanisms are recommended for optimal performance.Q: What are the benefits of using these fire doors?

A: Benefits include robust safety, high durability due to premium materials, optimal airflow support, and suitability for varied installations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Clean Room Partition Panels Category

EMERGENCY DOUBLE DOOR WITH PANIC BAR

Price 35000.0 INR

Minimum Order Quantity : 1

Material : Stainless steel

Frame Material : Stainless Steel

Type : Other

Door : YES

EMERGENCY SINGLE DOOR WITH PANIC BAR

Price 23000.0 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Galvanized steel

Frame Material : Stainless Steel

Door : Yes

Modular Clean Room PUFF Panel

Price 1950.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Galvanized steel

Frame Material : Stainless Steel

Type : Modular Clean Room

PUFF PANEL CLEAN ROOM 80 MM

Price 2050.0 INR / Piece

Minimum Order Quantity : 1 Unit

Material : Stainless steel

Frame Material : Stainless Steel

Type : Modular Clean Room

Door : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese