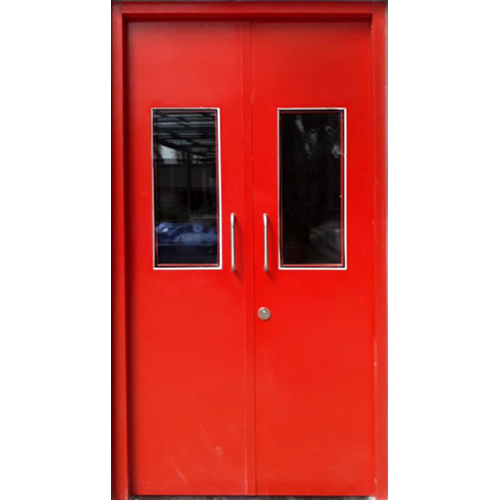

Price 1900.0 आईएनआर/ Meter

Specification

- फ़्रेम सामग्री

- मोटाई

- मिलीमीटर (mm)

- मटेरियल

- टाइप करें

- दरवाज़ा

- Yes

- फ़ीचर

- Good Quality

Trade Information

- Minimum Order Quantity

- 1 Meter

- डिलीवरी का समय

- दिन

About

Pharmaceutical Clean Room

Short Description:

A Pharmaceutical Clean Room is a controlled environment designed to maintain extremely low levels of airborne particles, temperature, and humidity. It ensures contamination-free production, packaging, and testing for pharmaceutical and healthcare industries.

Specifications:

-

Classifications: ISO 5, ISO 6, ISO 7, ISO 8 (as per requirement)

-

Air Filtration: HEPA/ULPA filters with 99.97% efficiency

-

Air Flow Type: Laminar / Turbulent airflow

-

Temperature Control: 18C 25C (adjustable)

-

Humidity Control: 40% 65% RH

-

Material of Construction: Powder-coated GI, SS 304 / SS 316

-

Lighting: LED with 300500 Lux

-

Applications: Tablet manufacturing, sterile injectables, R&D labs, packaging units, and quality control

High-Quality Modular Clean Rooms

Designed for pharmaceutical applications, our rooms provide top-notch quality, modularity, and durability.

Stainless Steel Construction

Constructed using stainless steel, these clean rooms offer excellent resistance to corrosion and easy maintenance.

FAQs of Pharmaceutical Clean Room:

Q: What is a Pharmaceutical Modular Clean Room?

A: A Pharmaceutical Modular Clean Room is a controlled environment, made with modular components, designed to maintain hygiene standards and prevent contamination during pharmaceutical manufacturing processes.Q: How does the clean room ensure quality and hygiene?

A: The clean room ensures quality by using high-grade stainless steel construction which resists contaminants and facilitates thorough cleaning, maintaining stringent hygiene standards.Q: Where can this modular clean room be installed?

A: This modular clean room can be installed in manufacturing facilities, research laboratories, and hospitals, wherever controlled environments are needed.Q: What is the process of setting up a modular clean room?

A: The process includes designing based on the application requirements, manufacturing prefabricated stainless steel components, and assembling them onsite.Q: What are the key benefits of using a stainless steel modular clean room?

A: Benefits include high durability, ease of maintenance, corrosion resistance, and flexibility to adapt to pharmaceutical industry standards.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese